Immersed in Durability: Hot-Dip Galvanized Square Pipes Shaping the Industry

In the ever-evolving landscape of construction and manufacturing, hot-dip galvanized square pipes emerge as a product synonymous with durability and resilience. Designed to withstand the test of time and elements, these pipes are not just another component; they are the backbone of enduring infrastructure. Today, we dive into the world of hot-dip galvanized square pipes to understand their nature and utility.

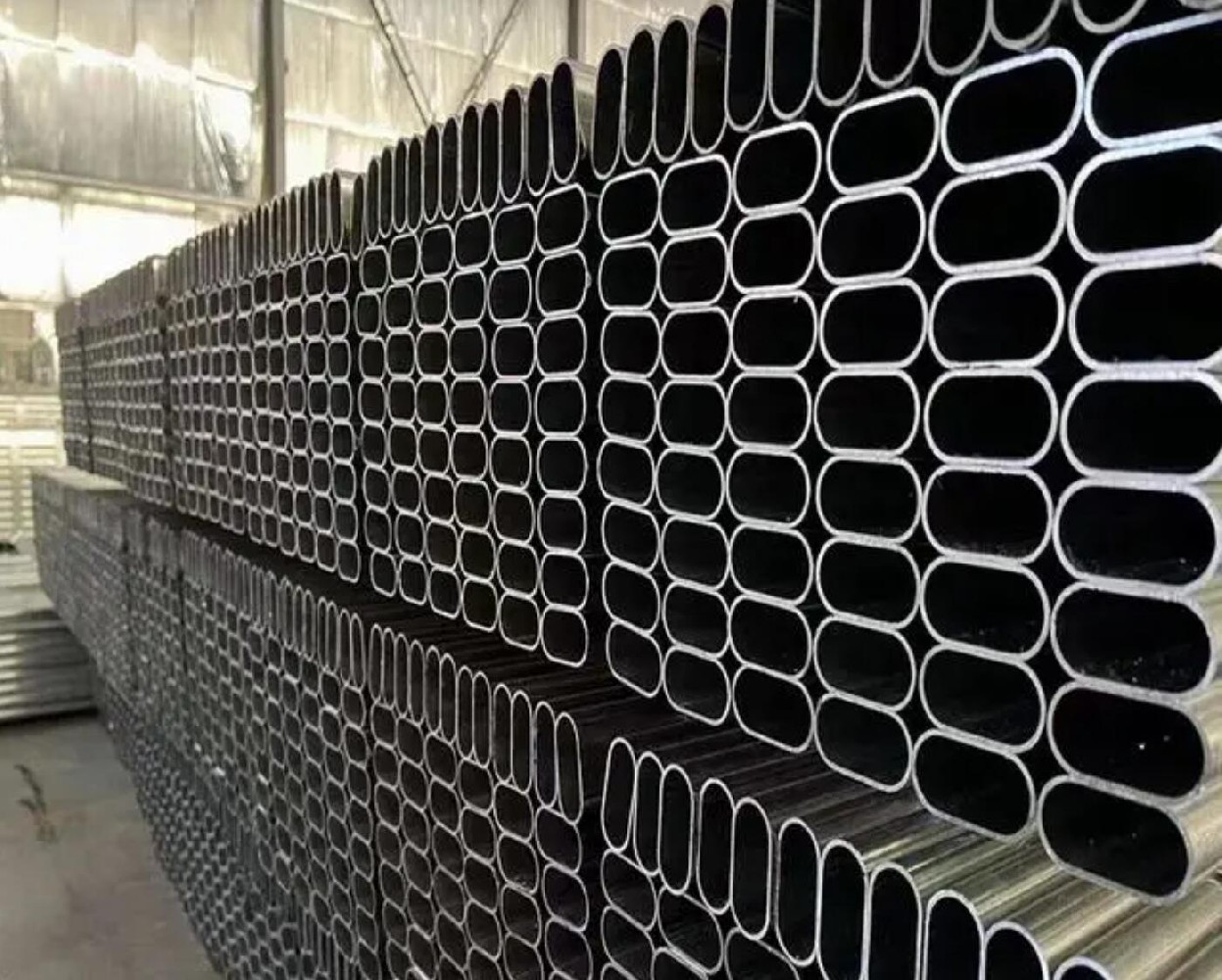

A Closer Look at Hot-Dip Galvanized Square Pipes

Hot-dip galvanized square pipes are steel pipes that have undergone a galvanization process, which involves the coating of the steel with a layer of zinc by immersing the metal in a molten zinc bath. This galvanization ensures a robust shield against corrosion and rust, making these pipes a preferred choice in challenging environments.

Characteristics That Stand Out

1. Corrosion ResistanceThe zinc coating provides a cathodic protection, which means it will sacrifice itself to protect the underlying steel from rust.

2. LongevityThese pipes are known for their extended lifespan, often exceeding that of the structure they are used in.

3. Aesthetic AppealThe smooth and shiny finish of galvanized pipes not only adds to the visual appeal but also provides a surface that requires minimal maintenance.

Versatile Applications Across Industries

1. Construction and ArchitectureHot-dip galvanized square pipes are widely used in construction for framing, fencing, and support structures due to their strength and resistance to environmental impact.

2. Industrial MachineryIn the realm of machinery and heavy equipment, these pipes serve as protective frames and supportive skeletons that can endure mechanical stress and environmental corrosion.

3. Agricultural ImplementationsThe agricultural industry benefits from these pipes in the construction of greenhouses and irrigation systems, where moisture resistance is critical.

4. Transportation InfrastructureGalvanized square pipes play a pivotal role in transportation, used in guardrails, signposts, and various components of public transport facilities.

The Process Behind the Product

The production of hot-dip galvanized square pipes involves precise engineering. The steel is cut to size, shaped into squares, and meticulously cleaned before being dipped into the molten zinc. Once removed, the metal cools and solidifies into a formidable, corrosion-resistant pipe.

Conclusion: A Structure's Silent Guardian

Hot-dip galvanized square pipes may go unnoticed by the casual observer, but their function is essential. They offer a strategic combination of strength, durability, and cost-effectiveness that few other materials can match.

Forging Ahead

As industries continue to demand materials that can stand up to increasingly harsh conditions, hot-dip galvanized square pipes will likely remain a key player, keeping structures standing tall and machinery moving smoothly for years to come.